Insights Into Material Handling and Industrial Magnets: A Comprehensive Guide

Material handling is a crucial aspect of various industries, ensuring the efficient movement, storage, and control of materials throughout the manufacturing process. One key element in material handling is the use of industrial magnets, which play a vital role in lifting, separating, and conveying materials. In this comprehensive guide, we will delve into the world of material handling and industrial magnets, exploring they're importance, applications, and various types. So, let's get started!

Understanding Material Handling

What is material handling, and why is it important?

Material handling refers to the movement, storage, control, and protection of materials during manufacturing, distribution, consumption, and disposal. It plays a critical role in streamlining operations, reducing costs, improving productivity, and ensuring workplace safety. Effective material handling systems optimize workflow, minimize downtime, and enhance overall efficiency.

What are the key components of material handling systems?

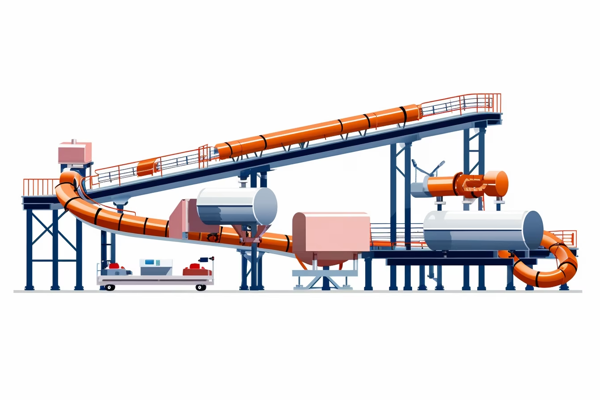

Material handling systems comprise various components that work together to facilitate the smooth flow of materials. These components include storage equipment, such as racks and shelves, conveying systems like conveyor belts and rollers, automated guided vehicles (AGVs), and

industrial magnets, among others.

What are the different types of material handling equipment?

Material handling equipment can be categorized into four main types: storage and handling equipment, engineered systems, industrial trucks, and bulk material handling equipment. Each type serves specific purposes, such as storing and retrieving materials, transporting heavy loads, or handling bulk materials like grains or liquids.

Unveiling the Power of Industrial Magnets

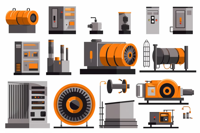

What are industrial magnets, and how do they work?

Industrial magnets are powerful devices that generate a magnetic field capable of attracting or repelling ferrous materials. They are widely used in material handling applications to lift, separate, and convey various types of metallic objects. Industrial magnets work based on the principles of magnetism, utilizing the inherent properties of certain materials to create a magnetic force.

What are the common types of industrial magnets?

There are several types of industrial magnets, each designed for specific applications. Some common types include:

- Ceramic Ring Magnets: These magnets retain their magnetic properties without the need for an external power source. They are commonly made from materials like neodymium, samarium-cobalt, or ceramic ferrite.

- Creative Hobbies Ceramic Industrial Magnets: Unlike permanent magnets, electromagnets require an electric current to create a magnetic field. They offer greater control over the magnetic force and can be turned on or off as needed.

- Ceramic Magnets: These specialized magnets are used to separate ferrous materials from non-ferrous ones. They are commonly employed in recycling plants, mining operations, and material recovery facilities.

- Magnetic Lifters: Designed for lifting and transporting heavy ferrous objects, magnetic lifters use powerful magnets to securely hold the load. They find applications in industries such as construction, metalworking, and logistics.

Where are industrial magnets used in material handling?

Industrial magnets find extensive use in various material handling applications. They are employed in industries such as manufacturing, automotive, mining, recycling, food processing, and logistics. Some common applications include:

- Lifting and moving heavy metal objects, such as steel plates, pipes, or machinery components using magnetic lifters.

- Separating ferrous materials from non-ferrous ones in recycling facilities using magnetic separators.

- Guiding and controlling the flow of materials on conveyor belts or production lines using industrial magnets.

- Holding and stabilizing objects during assembly or welding processes using magnetic lifters.

- Sorting and inspecting materials for quality control purposes using magnetic separators.

What factors should be considered when selecting industrial magnets?

Choosing the right industrial magnet for a specific application requires careful consideration of various factors. Some key factors to keep in mind include:

- Magnetic strength: The magnet should possess sufficient strength to handle the intended load or material.

- Environmental conditions: Considerations such as temperature, moisture, and corrosive substances can impact magnet performance and durability.

- Size and shape: The magnet's dimensions should match the requirements of the application, ensuring proper fit and functionality.

- Power source: Depending on the application, you may need to decide between permanent magnets or electromagnets powered by electricity.

- Safety: Proper safety measures should be taken to ensure the magnets are used correctly and do not pose hazards to operators or the surrounding environment.

In Conclusion

Material handling and industrial magnets are integral components of many industries, facilitating the smooth and efficient movement of materials. Understanding the importance of material handling systems and the various types of industrial magnets available helps optimize workflow, improve productivity, and ensure workplace safety.

As technology continues to advance, the use of industrial magnets in material handling is likely to evolve, offering even more efficient and innovative solutions. By staying informed about the latest developments and selecting the appropriate industrial magnets for specific applications, businesses can enhance their material handling processes and gain a competitive edge.

Remember, whether it's lifting heavy loads, separating materials, or controlling the flow of materials on a production line,

industrial magnets are an indispensable tool in the realm of material handling. So, leverage their power wisely and unlock the full potential of your operations!

Note: The information provided in this article is for educational purposes only and does not constitute professional advice. Always consult with experts or manufacturers for specific recommendations and guidance related to your material handling needs.

Littleredmonkey - October 17, 2023

Wow, this guide is really helpful! I never knew there was so much to learn about material handling and industrial magnets. Thanks for sharing all this valuable information!

bootie_crickets - October 16, 2023

Thanks for the info!